Easy Sleeve Maintenance System for Continuous Miners, Longwall Shearers, Roadheaders & Surface Miners

Enhance Productivity • Improve Safety • Lower Mining Costs

Change the Sleeve, Not the Drum

Common Challenges in Cutting Systems

Mining environments for coal, potash, salt, trona, and polyhalite place extreme wear on cutter drums, pick boxes, carbide cutting tools, and pick sleeves. Traditional hydraulic sleeve extractors struggle with misalignment, increasingly so as pick boxes wear, making maintenance time-consuming and hazardous.

The Easy Sleeve Advantage for Drum Miners

Improve Safety

- Eliminate use of cutting torches, sledgehammers, and chain lanyards to extract sleeves on worn drums.

- Lightweight, self-aligning hydraulic tools reduce fatigue and reduce pressures.

- Lower extraction pressures minimise risk of incidents.

Reduce Costs

- Extend cutter drum and pick box life across continuous miners, Longwall Shearers and surface miners.

- Simplify maintenance operations in challenging mining conditions.

Enhance Productivity

- Extraction and installation in under 3 minutes.

- Always works regardless of pick box wear ensures reliability in trona, salt, and tunnelling projects.

How Easy Sleeve Works in Cutting and Tunnelling Operations

Installation

Extraction

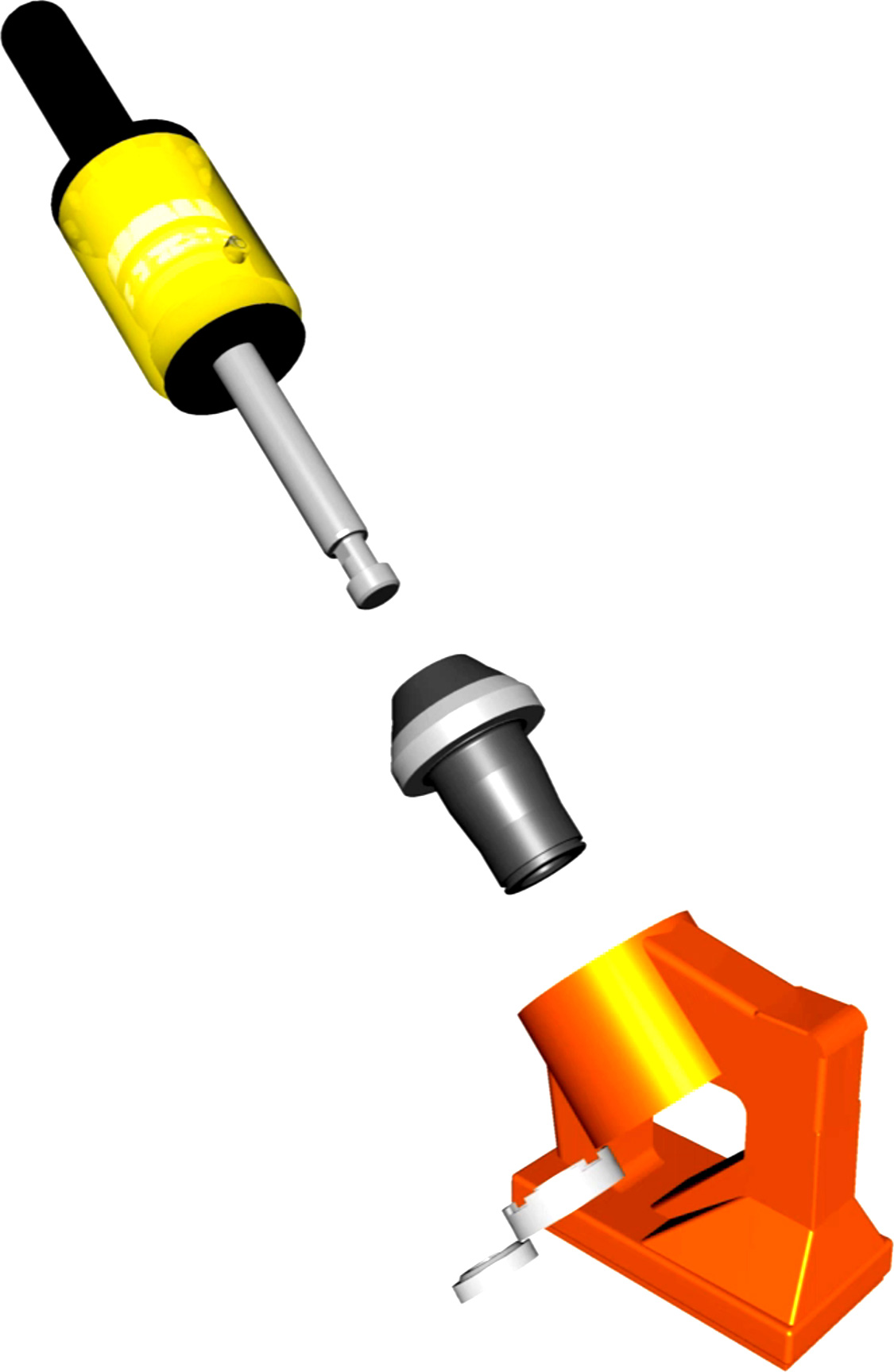

Easy Sleeve Components for Cutting Efficiency

Extractor Tool

Hydraulic Trolley

Safety Guard

Extraction Cup

Insertion Ring

Horseshoe Clip

Mining Sectors Benefiting from Easy Sleeve

Underground Coal Mining

Potash Mining

Salt Mining

Trona Mining

Polyhalite Mining

Hard Rock Tunnelling

Surface Miner Equipment Maintenance

Field-Proven Success in Mining and Tunnelling

- Easy Sleeve was trialed in tough conditions at Sasol, a South African coal mine, from April 2023.

- Over 1.6 million tonnes life on cutter drum due to improved and regular maintenance.

- Sleeve removal and installation time reduced to 2.5 minutes each.

- No flame torching, no pick shanking.

- Doubled service intervals of cutter drums, due to elimination of flame cutting.

- Preferred by maintenance personnel.

- Now installed on 12 machines and increasing.

Frequently Asked Questions

Can Easy Sleeve retrofit onto my existing continuous miner?

Yes. Easy Sleeve is fully compatible with existing continuous miner, surface miner, longwall shearer, and tunnelling cutting systems. It does not require modification to your cutter drum, pick blocks, or machine design. The sleeve dimensions and appearance match standard sleeves to ensure seamless integration.

Does the two-part sleeve impact wear life or durability?

Are special tools needed to install or extract Easy Sleeves on conical bits?

No. Easy Sleeve uses a specifically designed hydraulic extractor and insertion system, but it works with your standard conical bits and carbide cutting tools. There is no need to change your cutting picks or existing block setups. The system is engineered for ease of use without additional modifications to cutting components.

Is Easy Sleeve compliant with mining standards and certifications?

Yes. Easy Sleeve is designed and manufactured in accordance with relevant Australian mining equipment standards and has been awarded Australian Patent No: 2019237295. The system also follows best practices for operator safety, pressure handling, and mechanical design expected in global mining operations.

How much time does Easy Sleeve save compared to traditional sleeve removal?

Typical sleeve removal with traditional hydraulic tools can take 4+ hours per drum. Easy Sleeve reduces sleeve extraction and installation to approximately 2–3 minutes per sleeve. Mines trialling Easy Sleeve have reported entire drum maintenance times reduced by over 80%, leading to lower downtime and increased operational productivity.

Can Easy Sleeve be used on worn pick boxes and damaged drums?

Yes. Unlike traditional hydraulic extractors that lose effectiveness as blocks wear, Easy Sleeve locates directly on the collar of the sleeve and functions independently of block wear. This means it continues to operate safely and efficiently even when the pick box has experienced significant erosion or wear.

Does using Easy Sleeve improve overall drum life?

Yes. Mines trialling Easy Sleeve have observed up to double the drum service life. By making sleeve maintenance faster, easier, and safer, mining operations maintain better pick retention, reduce pick shanking, and minimise block damage — all contributing to longer-lasting drums.

Is specialised training required to use Easy Sleeve?

Minimal. Operators familiar with standard hydraulic sleeve extraction methods will find Easy Sleeve intuitive and straightforward. A short demonstration and basic training session are sufficient for safe and effective use, thanks to the system’s self-aligning, lightweight design and built-in safety features like the pressure gauge and guard.

Request A Demo

Experience how Easy Sleeve can lower mining maintenance costs and maximise equipment uptime across coal, potash, salt, trona, polyhalite, and tunnelling operations.

Easy Sleeve Configuration Questionnaire

Document Downloads

Easy Sleeve Maintenance System for Continuous Miners & Surface Miners

Enhance Productivity • Improve Safety • Lower Mining Costs